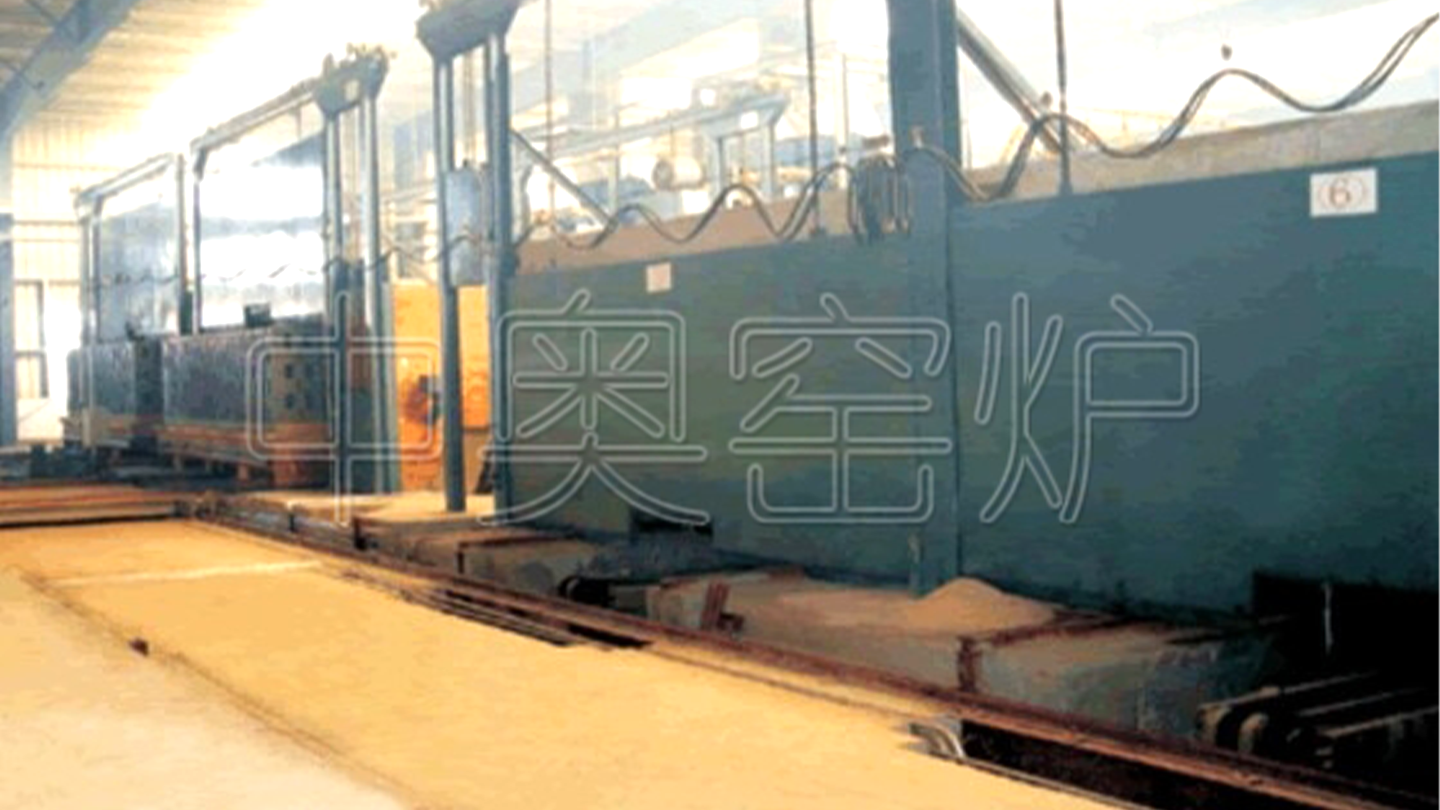

With the booming development of the steel, glass, cement, and ceramics industries, the demand for high-quality refractory materials in high-temperature production processes continues to rise. To meet this demand and improve the production efficiency and quality of refractory materials, the refractory materials tunnel kiln project is being actively promoted.

alkaline refractory materials ultra-high temperature tunnel kiln

With the advancement of industries such as steel and non-ferrous metal smelting towards high-end applications, the performance requirements for alkaline refractory materials are becoming increasingly stringent, and ultra-high-temperature firing has become a key step in improving their quality. Against this backdrop, the ultra-high-temperature firing tunnel kiln project for alkaline refractory materials has emerged to meet the urgent industry demand for high-quality alkaline refractory materials.

10.3-meter-wide coal gangue brick tunnel kiln

Driven by the green development trend in the construction industry, the demand for environmentally friendly wall materials is steadily increasing. Coal gangue bricks, with their energy-saving and waste-reducing properties, have gained significant popularity. To improve the production efficiency and quality of coal gangue bricks, a 10.3-meter wide coal gangue brick tunnel kiln project has been launched.

In the wave of pursuing efficient and high-quality production in the ceramic, refractory materials, and building materials industries, higher demands are placed on the performance and capacity of kiln equipment. The 9.0-meter wide tunnel kiln project was launched to meet this trend, aiming to provide advanced firing solutions for related industries.

With the continuous development of the ceramic, refractory materials, and building materials industries, the demand for refined and efficient kiln equipment is becoming increasingly prominent. Against this backdrop, the 6.9-meter-wide tunnel kiln project has emerged to provide a more suitable firing solution for these industries.

In today's ceramics, brick and tile, and special materials industries, where the pursuit of refinement and energy efficiency is ongoing, increasingly stringent demands are placed on kiln equipment. The 4.6-meter inner-width tunnel kiln project is a direct response to this trend, dedicated to providing highly efficient and high-quality firing solutions for related industries.

Anhui Liuan Iron and Steel Group's five 600T annual output double-shaft lime kilns

In the steel industry's ongoing pursuit of high quality, low cost, and green development, high-quality lime, as a key metallurgical auxiliary material, is crucial for stable supply and high-quality assurance. Anhui Liuan Iron and Steel Group, in order to strengthen its competitiveness in the industry and improve production efficiency and product quality, is fully promoting the construction of a project with five 600T double-Mertz lime kilns with an annual output.

Malaysia's United Steel four 600T annual output twin-hearth lime kilns

Against the backdrop of increasingly fierce competition in the global steel industry and the growing pursuit of green and efficient production, high-quality lime, as an indispensable key auxiliary material in steel smelting, plays a decisive role in the production efficiency and product quality of steel enterprises through its stable and high-quality supply. In order to enhance its competitiveness in the international steel market, Malaysia's United Steel is fully promoting the construction of a project with four 600T twin-shaft lime kilns with an annual output.

Guangxi Liuzhou Shanhai Technology's four 600T annual output hanging cylinder lime kilns

With the booming development of the construction, metallurgy, and chemical industries, the demand for high-quality lime continues to grow, and the requirements for efficient and environmentally friendly production processes are becoming increasingly stringent. Guangxi Liuzhou Shanhai Technology is fully promoting the construction of a project with four 600T annual output hanging-cylinder lime kilns to meet market trends and enhance its competitiveness in the lime production field.

Against the backdrop of comprehensively advanced infrastructure construction and accelerating urbanization, cement, as a core material in the construction industry, shows a sustained growth trend in market demand. To meet this demand and improve the quality and efficiency of cement production, the cement rotary kiln project has emerged.

Driven by the booming development of numerous industries such as coatings, ceramics, electronics, and magnetic materials, the demand for high-quality iron oxide has seen explosive growth. To meet this market demand and improve the quality and efficiency of iron oxide production, the iron oxide calcination rotary kiln project has emerged.

Twin/single-shaft lime vertical kiln

With the continuous development of the steel, chemical, and construction industries, the demand for lime is increasing day by day, and the requirements for lime quality are becoming increasingly stringent. In order to meet market demand and improve lime production efficiency and quality, double-body/single-body lime vertical kiln projects are being actively promoted.

Contact Us

Tel: 86-0713-8663193

Yu Yuanlin: 86-13871998019

Hong Hui: 86-13907259535

Yu Shiyun: 86-17798384875

E-mail:zhongaokiln@163.com

Address: Building A3, Guanggu United Science and Technology City, Huangzhou District, Huanggang City, Hubei Province