Technical support required for the intelligent upgrading of the coke industry

Release time:

2025-03-21

In the process of intelligent upgrading in the coke industry, various advanced technologies play an indispensable role.

In the process of intelligent upgrading in the coke industry, various advanced technologies play an indispensable role.

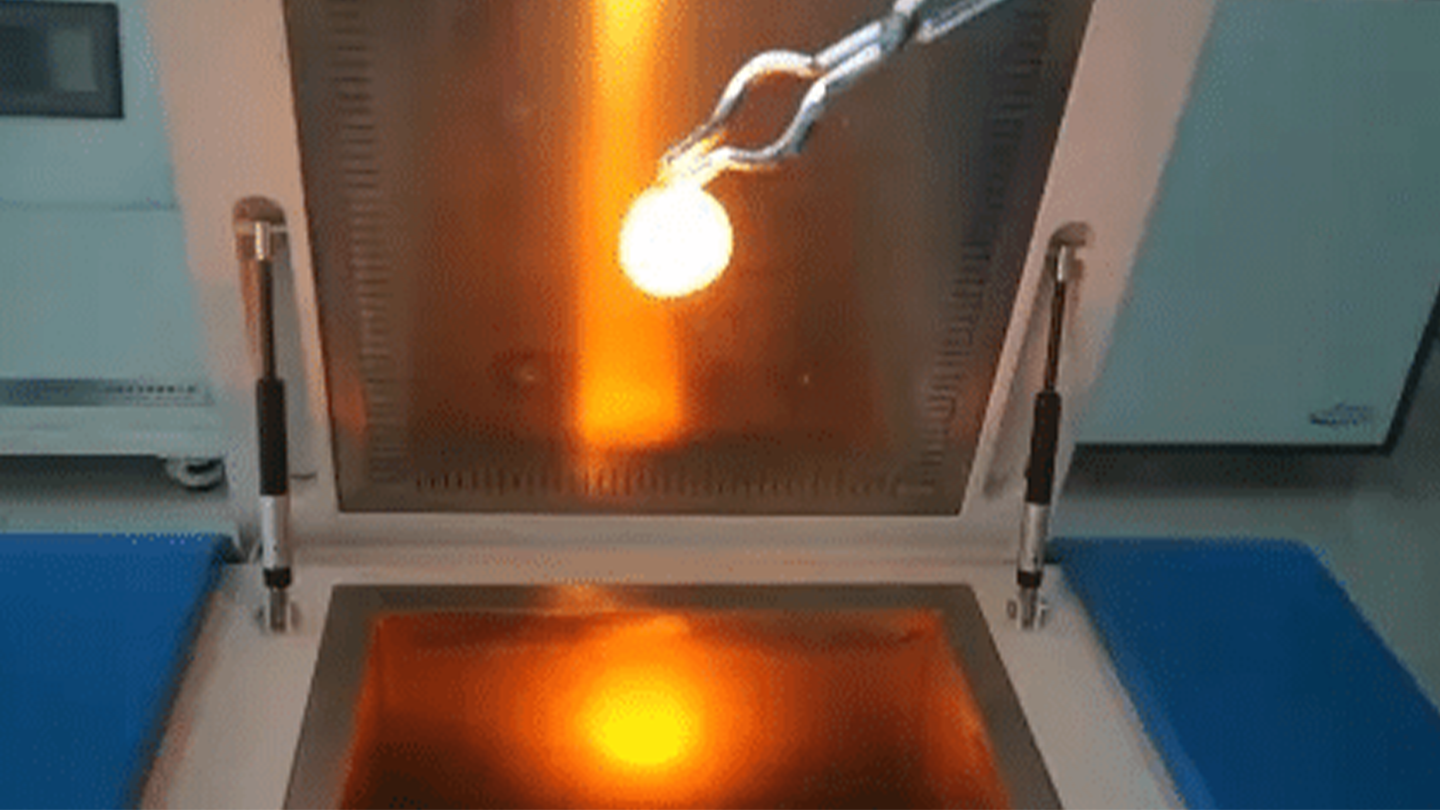

First is the Internet of Things (IoT) technology. By deploying a large number of intelligent sensors in production equipment, transportation vehicles, and warehousing facilities, a comprehensive IoT system is built. These sensors can collect massive amounts of data in real time, such as temperature, pressure, humidity, and equipment operating status, and transmit it to the data center. Taking the coke oven as an example, IoT technology can monitor the changes in the furnace temperature in real time, precisely control the coking process, and ensure the stability of coke quality.

Big data and cloud computing technologies are also crucial. Big data technology performs in-depth mining and analysis of the massive amount of data collected by the Internet of Things, extracting valuable information such as equipment fault warnings and production efficiency optimization points. Cloud computing provides powerful computing capabilities for data storage and complex calculations, ensuring the efficiency and timeliness of data processing. Based on big data analysis, enterprises can accurately adjust the raw material ratio according to historical production data and market demand forecasts, improve production efficiency, and reduce costs.

Automation control technology is also the key to intelligent upgrading. On the coke production line, from the automatic conveying and precise proportioning of raw materials, to the automatic adjustment of temperature and pressure during the coking process, and to the automatic sorting and packaging of products, automation control technology is ubiquitous. For example, automated coal loading vehicles can accurately load coal into coke ovens according to preset programs, reducing manual operation errors and improving the accuracy and consistency of production.

Artificial intelligence and machine learning technologies also play an important role. Using artificial intelligence algorithms to learn from equipment operation data can achieve intelligent diagnosis of equipment failures and predictive maintenance. Machine learning models can automatically optimize production parameters based on real-time production data, improve the intelligence level of the production process, reduce reliance on manual experience, and improve overall production efficiency.

These technologies are integrated and work together to lay a solid foundation for the intelligent upgrading of the coke industry and help the industry achieve high-quality development in the new era.

Tag:

Contact Us

Tel: 86-0713-8663193

Yu Yuanlin: 86-13871998019

Hong Hui: 86-13907259535

Yu Shiyun: 86-17798384875

E-mail:zhongaokiln@163.com

Address: Building A3, Guanggu United Science and Technology City, Huangzhou District, Huanggang City, Hubei Province