Our country has successfully mastered microwave high-temperature sintering technology

Release time:

2019-01-22

China Aerospace Science and Industry Corporation's 068 base has successfully developed a continuous microwave high-temperature sintering roller kiln. This project uses microwave technology and is equipped with a highly efficient waste cleaning system, which reduces the huge energy consumption in the sintering process. Compared with the traditional three-push plate electric kiln, based on the calculation of 0.76 yuan per kilowatt-hour, each microwave kiln will save 1.56 million yuan in electricity costs per year, saving more than 70% of electricity costs.

China Aerospace Science and Industry Corporation's 068 base has successfully developed a continuous microwave high-temperature sintering roller kiln. This project utilizes microwave technology and is equipped with a highly efficient waste cleaning system, reducing the substantial energy consumption of the sintering process. Compared to traditional three-push plate electric kilns, each microwave kiln will save 1.56 million yuan in electricity costs annually, based on a cost of 0.76 yuan per kilowatt-hour, resulting in more than 70% savings in electricity costs.

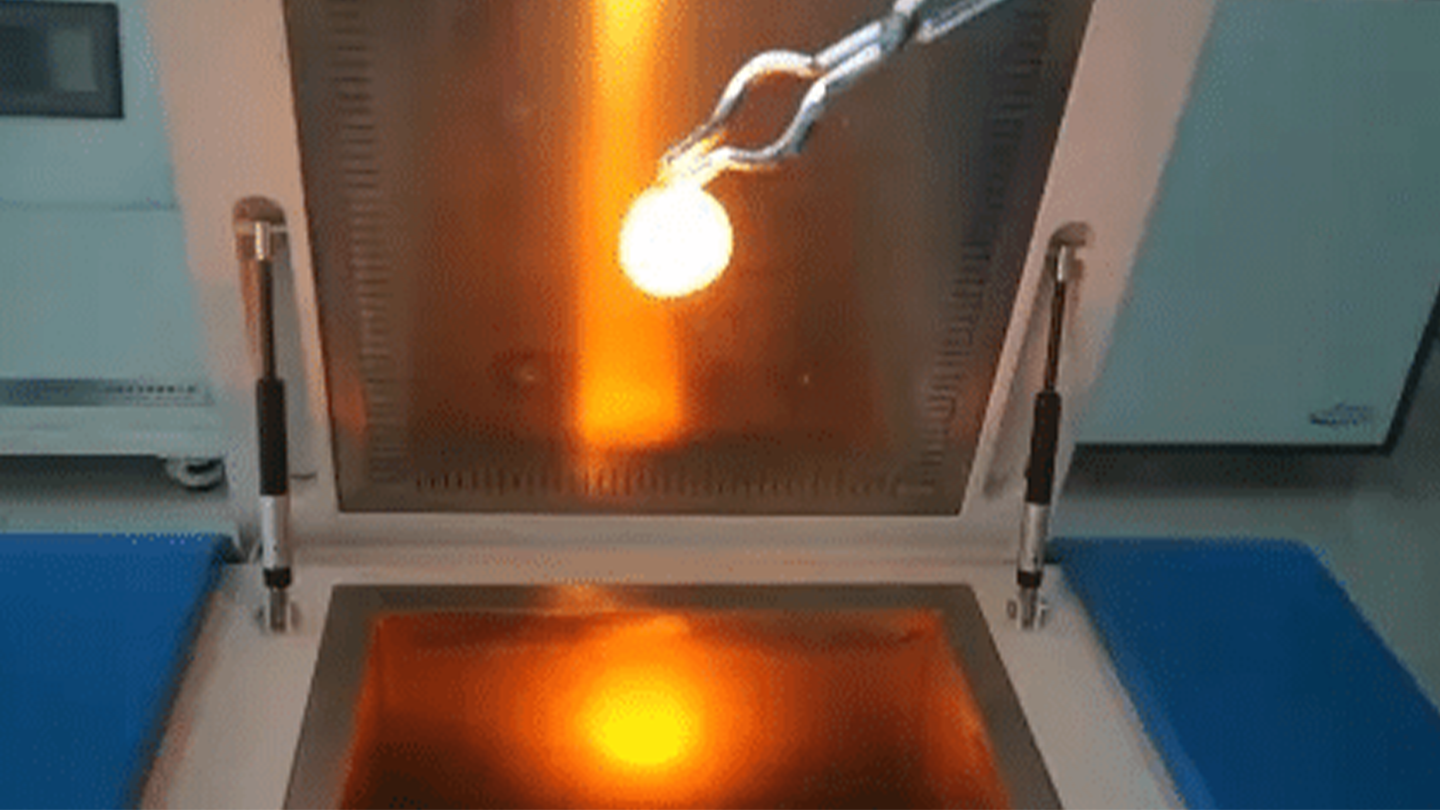

Recently, the 068 base has independently developed an advanced kiln precise temperature control and automatic safety protection system. In addition, the base has successfully completed the assembly and commissioning of a 2-meter experimental kiln, achieving the expected goal of one-time ignition of the experimental kiln. The sintered product performance fully meets the standards, and zero microwave leakage has been achieved, meeting national safety standards. The successful ignition marks the 068 base's successful entry into the microwave high-temperature sintering industry, becoming one of only two companies nationwide to master microwave high-temperature sintering technology.

It is understood that this microwave kiln has innovated in the sintering process of permanent magnet ferrite materials, which helps to solve a series of problems such as long sintering time, low product yield, poor consistency, and high loss in the permanent magnet ferrite process, thereby improving the automation level and potential economic value of the entire production process.

Currently, the project R&D team is actively writing and applying for patents. In addition, the 068 base will continue to promote the assembly, commissioning, and ignition of a 30-meter industrial microwave sintering kiln, and will carry out industrial production of microwave high-temperature sintering of permanent magnet ferrite materials on this basis.

Tag:

Contact Us

Tel: 86-0713-8663193

Yu Yuanlin: 86-13871998019

Hong Hui: 86-13907259535

Yu Shiyun: 86-17798384875

E-mail:zhongaokiln@163.com

Address: Building A3, Guanggu United Science and Technology City, Huangzhou District, Huanggang City, Hubei Province