Ceramic fiber brings a revolution to industrial kilns

Release time:

2021-11-09

Ceramic fiber is a fibrous, lightweight refractory material, the main chemical component of which is alumina silicate. According to its mineral composition, it can be divided into two categories: glassy fiber and polycrystalline fiber. Glassy fiber is an amorphous solid fiber formed by the cooling of molten liquid; polycrystalline fiber is mostly made by the sol-gel spinning method (or centrifugal spinning method), and is formed by high-temperature calcination.

Ceramic fiber is a fibrous, lightweight, refractory material whose main chemical component is alumina silicate. According to its mineral composition, it can be divided into two major categories: glassy fiber and polycrystalline fiber. Glassy fiber is an amorphous solid fiber formed by the cooling of a molten liquid state; polycrystalline fiber is mostly made by the sol-gel blowing method (or spinning method) and then fired at high temperatures.

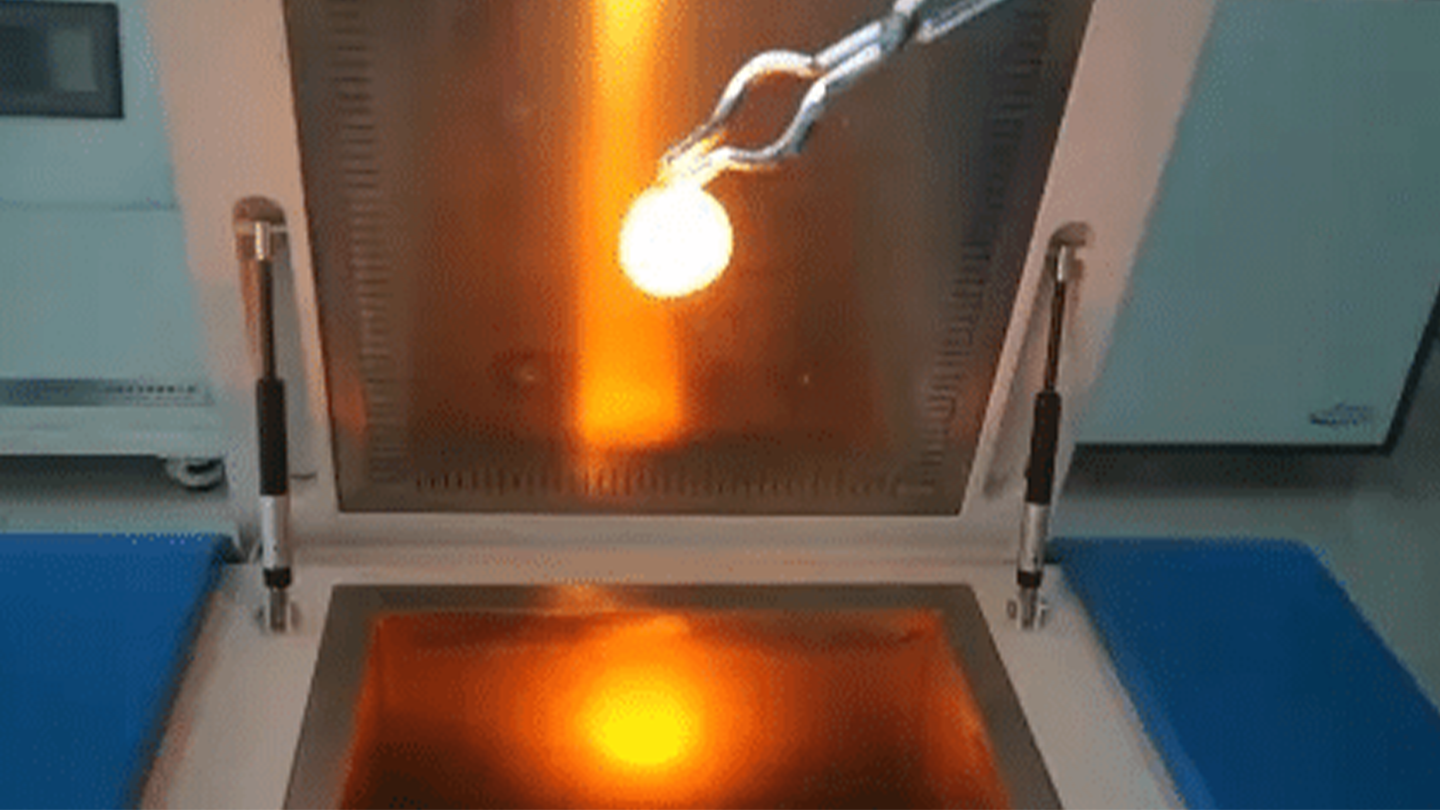

Ceramic fiber is widely used as a heat-insulating and high-temperature-resistant material in various thermal kilns. Because its density is much lower than that of other refractory materials, its heat storage is very small, and its heat insulation effect is significant. As a furnace lining material, it can greatly reduce the energy consumption of thermal kilns, bringing about a revolution in energy saving for thermal kilns. On the other hand, its application technology and methods have also revolutionized the construction of thermal kilns.

Ceramic fiber first appeared in 1941, when the American company Babb & Wilcox used natural kaolin to melt and blow fibers using an arc furnace. In the late 1940s, two American companies produced alumina silicate fibers and first applied them to the aerospace industry; in the 1960s, the United States developed various ceramic fiber products and used them in industrial kiln linings. In the 1970s, ceramic fiber began to be produced and used in China, and its application technology was rapidly promoted in the 1980s, but the main applicable temperature range was below 1000℃, and the application technology was relatively simple and backward. After entering the 1990s, with the promotion and application of zirconia-containing fibers and polycrystalline alumina fibers, the usable temperature increased to 1000℃~1400℃, but due to product quality defects and backward application technology, the application fields and methods were limited. For example, polycrystalline alumina fiber cannot be made into fiber blankets, and the product specifications are single, mainly loose cotton and fiber blocks. Although the usable temperature has increased, the strength is very poor, limiting the range of applications and shortening the service life.

Zirconia-containing fiber is a type of alumina silicate fiber produced by the melting method. It is widely used and relatively low in cost. It can be used in large quantities as a full-fiber lining for the hot face of various thermal kilns. Currently, the quality and application development of domestic products in this area are relatively backward. Chromium-containing fibers have emerged abroad, with a higher usable temperature than zirconia-containing fibers. There are no reports on this in China.

The main types of ceramic fibers include: ordinary alumina silicate fiber, high-alumina alumina silicate fiber, alumina silicate fiber (Cr2O3, ZrO2), polycrystalline alumina fiber, and polycrystalline mullite fiber, etc. In recent years, some new types of ceramic fibers have been successfully developed (or are being developed) abroad, such as magnesium olivine fiber, ceramic fiber (SiO2-CaO-MgO and Al2O3-CaO systems), etc. Ceramic fiber cotton, felt, blanket, module, paper, cloth, tape, rope, etc. [PAGE]

Ceramic fiber blanket (fiber module): Mostly made using a self-melting and continuous spinning production process to produce spun long fibers, which are then interwoven using double-sided needling. It can be directly used as a flame hot face, combining fire resistance, heat insulation, and heat preservation. It can maintain good strength and toughness even after long-term use in neutral, oxidizing, and slightly reducing atmospheres. The fiber modules made of this fiber blanket do not contain any binder, have good thermal stability, and are widely used in heat insulation and heat resistance fields such as petrochemicals, metallurgy, and power generation.

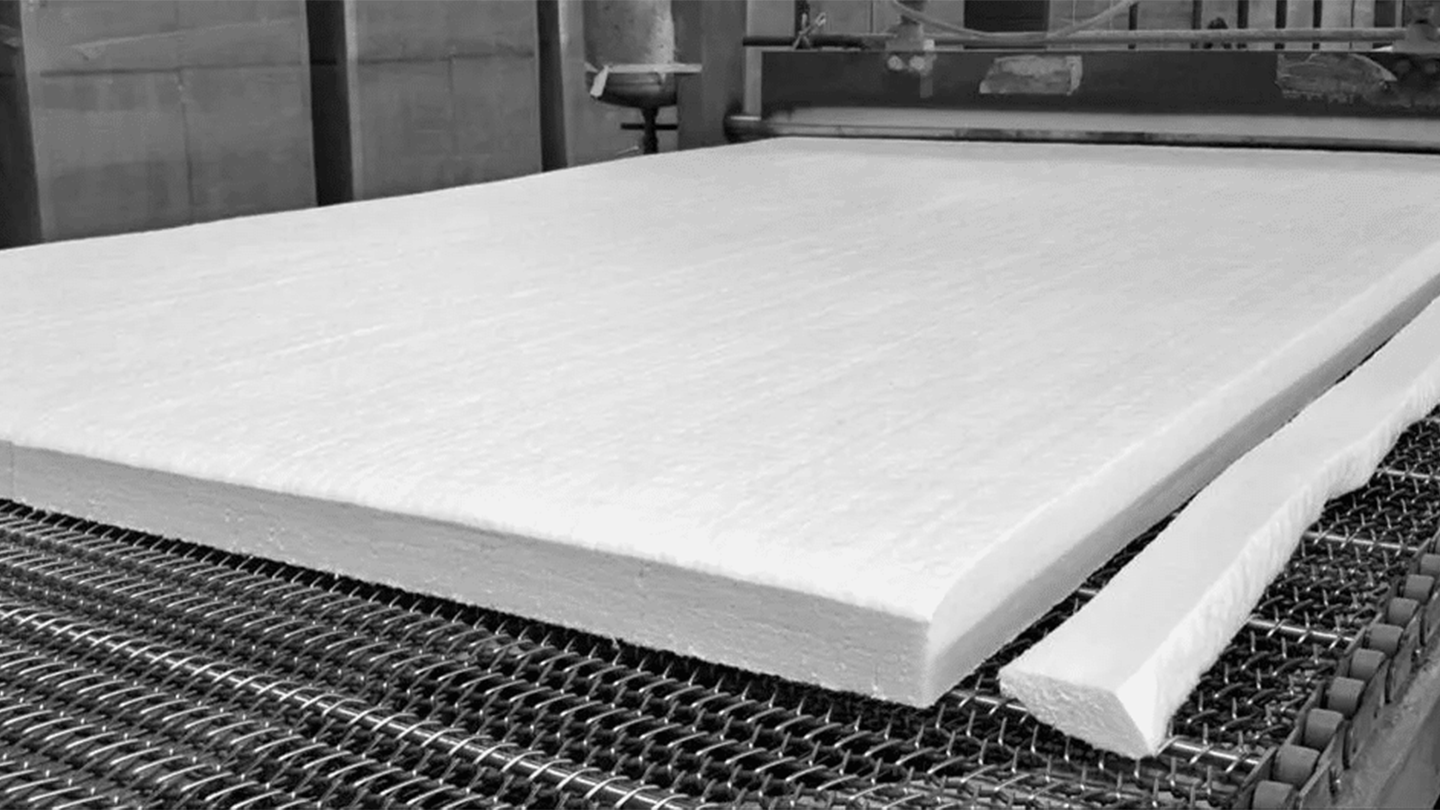

Ceramic fiber board: Made from ceramic fiber, binder, and additives through processes such as pulping, molding, curing, and drying. Ceramic fiber board has good flexibility, is easy to cut, and has high strength. It is a new type of energy-saving and environmentally friendly product with low thermal conductivity and low heat storage, and is widely used as a backing in various heating equipment walls and tops, belonging to heavy refractory materials.

Ceramic fiber cloth and tape: Mainly used in fire doors, industrial kiln heat insulation, and heat insulation of high-temperature pipes and containers.

Ceramic fiber rope: Mainly used for expansion joints in various industrial kilns, winding insulation of high-temperature pipes, and heat insulation of steel structure connections.

Ceramic fiber paper: Made from ceramic fiber, binder, and additives through processes such as pulping, molding, curing, and drying. It is an ideal material for sealing and heat insulation. It can be used for heat insulation and heat preservation in various thermal kiln expansion joints and high-temperature pads.

In addition, ceramic fiber can also be used in filter and catalyst carrier materials, filling materials and friction materials, thermal insulation coatings, reinforcing materials, etc.

Although ceramic fiber plays an important role in the heat insulation and fire resistance of high-temperature industrial fields, it also has significant production drawbacks, especially its inhalable nature, which poses certain hazards to the environment and human body. Some foreign companies have strengthened restrictions on the use of amorphous ceramic fibers. Currently, a biodegradable amorphous ceramic fiber has appeared in the heat insulation and refractory material market. This super fiber (SiO2-CaO-MgO system ceramic fiber) is an environmentally friendly material with no pollution. The future production trend of ceramic fiber products is towards non-pollution, refinement, and multi-functionality, especially the use of new technologies and new raw materials to prepare high value-added, high-tech functional fine ceramic fibers, the production probability of which will become increasingly greater, which is of great significance for Zhejiang's optimization of heat-insulating refractory materials.

Tag:

Contact Us

Tel: 86-0713-8663193

Yu Yuanlin: 86-13871998019

Hong Hui: 86-13907259535

Yu Shiyun: 86-17798384875

E-mail:zhongaokiln@163.com

Address: Building A3, Guanggu United Science and Technology City, Huangzhou District, Huanggang City, Hubei Province