Latest Advances in All-Electric Melting and Electrically-Boosted Melting Furnace Technology for Glass

Release time:

2019-01-22

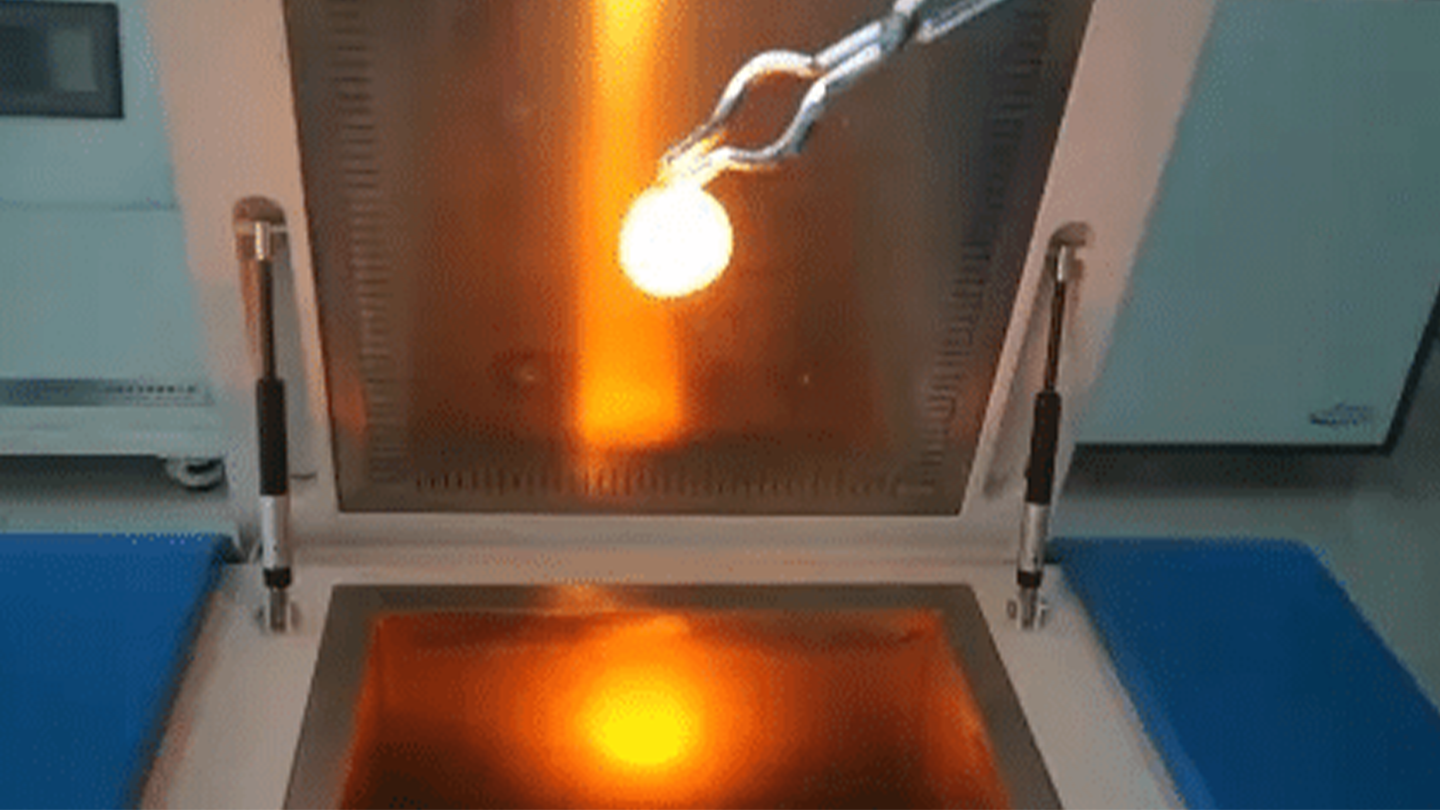

With the development of molybdenum electrode research, and especially the safe application of molybdenum electrodes, the commercialization of glass electrosmelting and electroboosting has been advanced. Approximately 60 years ago, American Larry Penberthy first used electroboosting. In the early stages of electroboosting technology development, a dedicated electrode cooling system was needed to ensure that the molybdenum electrode was not oxidized at 600℃. The first electrode cooling water jacket used a spray cooling structure. The water jacket was a tubular structure, and the internal water pipe sprayed cooling water to the end of the water jacket. Then, the water flowed back along the molybdenum electrode, and finally entered the water pool of the water circulation system through the return water pipe. This water jacket was significantly effective and was a fairly good cooling device for sidewall electrodes. The water jacket structure was simple, practical, and had low energy consumption. Of course, it also had disadvantages and shortcomings. This spray cooling water jacket did not have high requirements for the water quality of the circulating water, but it is not very suitable for today's increasingly large glass electrosmelting furnaces.

1. Introduction to Water Jackets

With the research and development of molybdenum electrodes, and especially the safe application of molybdenum electrodes, the commercialization of glass electrosmelting and electro-assisted melting has been advanced. Approximately 60 years ago, American Larry Penberthy first used electro-assisted melting. In the early stages of electro-assisted melting technology development, in order to safely use molybdenum electrodes, a special electrode cooling system was needed to ensure that the molybdenum electrode was not oxidized at 600℃. The first electrode cooling water jacket used a spray cooling structure. The water jacket was a tubular structure, and the internal water pipe sprayed cooling water to the end of the water jacket. Then, the water flowed back along the molybdenum electrode, and finally, it entered the water pool of the water circulation system through the return water pipe. This water jacket is significantly effective and is a fairly good cooling device for sidewall electrodes. This water jacket structure has advantages such as simplicity, practicality, and low energy consumption; of course, it also has disadvantages and shortcomings. This spray cooling water jacket does not have high requirements for the water quality of the circulating water, but it is not very suitable for today's increasingly large-scale glass electrosmelting furnaces.

With the increase in furnace size and the realization of more effective bottom-inserted electrode technology, an improved electrode water jacket has been formed, namely, a water jacket with an internal waterway. This type of water jacket is widely used in the current glass industry, but it also has many shortcomings, mainly: (1) easy to clog; (2) it places anti-thermal shock requirements on the surrounding refractory materials; (3) there is a certain danger in pushing the electrode; (4) it is difficult to recycle and reuse in the later stages of furnace use.

2. Water Jackets for Advanceable Electrodes

In recent years, the service life of furnaces has increased rapidly, requiring cooling water jackets to be usable for 15 years in continuous operation.

The biggest problem with electrode water jackets is the electrode advancement process. According to the electrode advancement design, the fastest is generally once every 3 months, and the slowest is once every 7 years, such as the float glass furnace designed by FIC. The difference in advancement time is so large mainly due to the type of glass, melting rate, and especially the advancement design structure. Electrode water jackets are usually damaged during the advancement process. The reason is mainly that in order to advance the electrode, the cooling water needs to be turned off, causing the overall temperature of the water jacket to rise, causing the solidified glass near the water jacket to soften to achieve the purpose of advancement. Almost all electrode water jackets are made of heat-resistant stainless steel and need to withstand high temperatures of 1100℃. However, after advancing the water jacket, the biggest problem is the re-entry of water into the water jacket. Because the temperature at the front end of the water jacket is as high as 1100℃, the cooling water needs to be added very slowly to prevent damage caused by a huge temperature difference. However, because the furnace operators are already hot and tired during the electrode advancement process and hope to finish the work early, the water is often not added slowly enough in actual operation.

Obviously, the cooling water causes thermal shock because it is injected too quickly. However, the time wasted during the advancement process, if not advanced in time, will also cause damage to the water jacket. Once thermal shock occurs, the water jacket welds will crack or the water jacket will become blocked, causing permanent damage to the water jacket, resulting in splashing and waste of cooling water. Because most current advancement systems are for vertical electrodes, the water loss flowing to the ground is very high, leading to drilling of the electrode or changing the electrode position. This is work that requires in-depth research and is expensive.

In addition, when advancing the electrode, the introduced cooling water will produce unobservable hot steam after reaching the high-temperature part of the water jacket, which can easily scald nearby operators. Regardless, the cooling water still needs to be introduced slowly. Some companies use air cooling systems to alleviate this process. Over time, even with treated water, the closed cooling water jacket will slowly become blocked, and eventually the cooling water will stop running, and spray cooling will have to be used. Sometimes, reverse flow of cooling water can also clear blocked water jackets. Another solution is to inject citric acid. If the cooling water flow in the water jacket decreases, the citric acid injected into the system can reduce the chance of the water jacket becoming blocked. When blockage occurs, some companies control the cooling circuit by opening another independent waterway. FIC developed a replaceable independent waterway, which later developed into multiple independent waterways.

3. New High-Quality Water Jackets

In summary, in these standard water jacket systems, the water-cooled spiral tube is the core part of the water jacket. It not only absorbs the heat from the front end of the water jacket but also absorbs the heat from the surrounding area of the water jacket. This also leads to heat absorption from the refractory material and causes star-shaped cracks. Some suppliers have recognized this problem and wrapped the water jacket with insulation material to reduce its impact. As early as 20 years ago, FIC invented a new water jacket that overcomes all the above shortcomings.

More than 7,000 FIC high-'Q' water jackets have been produced, representing the current advanced level. The detachable waterway is its main feature. This waterway can be disassembled by ordinary employees in less than ten minutes, requiring only three tools to completely separate and complete the entire process. Due to the large cross-sectional area, the requirements for the water quality of the cooling water are not high. In fact, if necessary, river water can be used directly. The detachable waterway does not directly contact the water jacket itself; it has an air gap to ensure that the cooling water only acts on the front end of the water jacket. This reduces or completely eliminates star-shaped cracks in the refractory material caused by thermal shock. In addition, this water jacket was designed by senior personnel with rich experience in electro-assisted melting and electric melting furnaces. Any potential failures and their solutions have been considered during the design process.

For example, to prevent the detachable waterway from sticking to other structures of the water jacket, a jacking system is designed to ensure the normal extraction of the waterway. Similarly, the thermocouple used to measure the temperature at the front end of the water jacket is independent. Therefore, it is necessary to more accurately measure the temperature of the high-temperature part of the water jacket and the refractory material, accurately display the softening point of the glass around the water jacket, and ensure the advancement of the electrode. This means that it is easy to determine when to advance the electrode. On this issue, it should be stated that the water jacket should never be advanced while using a water pressure water jacket. This will not only damage the surrounding refractory material but may also cause the entire water jacket to fall apart. FIC's fixing method is to use a screw structure to apply appropriate pressure to the electrode without damaging the electrode and refractory bricks. If too much pressure is applied, the screws will be damaged, but the refractory material and the water jacket itself will not be damaged. If necessary, these screws are easy to replace and are standard parts everywhere. If unexpected damage to the refractory material is found, this fixing structure can also pull out the water jacket if necessary.

Another important innovation of this high-'Q' water jacket is that it is not necessary to cut off the cooling water when advancing the electrode because the cooling water spiral tube is movable. The cooling water pipe is retracted to no longer contact the front end of the water jacket and the electrode, so the glass can naturally heat up. Because the cooling water is not stopped, there is no danger of producing superheated steam, and it will not cause burns to the workers. This is also an important feature of current occupational health and safety laws.

Tag:

Contact Us

Tel: 86-0713-8663193

Yu Yuanlin: 86-13871998019

Hong Hui: 86-13907259535

Yu Shiyun: 86-17798384875

E-mail:zhongaokiln@163.com

Address: Building A3, Guanggu United Science and Technology City, Huangzhou District, Huanggang City, Hubei Province