Iron oxide rotary kiln

Key words:

Classification:

Product Description

Driven by the booming development of numerous industries such as coatings, ceramics, electronics, and magnetic materials, the demand for high-quality iron oxide has seen explosive growth. To meet this market demand and improve the quality and efficiency of iron oxide production, the iron oxide calcination rotary kiln project has emerged.

This rotary kiln technology boasts significant advantages. The kiln body uses specially customized high-temperature and corrosion-resistant alloy steel, effectively resisting the high-temperature and strong oxidizing environment generated during iron oxide calcination, ensuring long-term stable operation of the equipment and reducing maintenance costs. The unique inclined cylinder design and precise rotary speed control allow the iron oxide material to achieve uniform tumbling and sufficient heating in the kiln, ensuring the consistency and efficiency of the calcination reaction, and greatly improving the stability of product quality. The advanced combustion system, through precise control of fuel injection volume, angle, and mixing ratio with combustion air, creates a stable high-temperature environment suitable for iron oxide calcination, significantly improving energy utilization efficiency and reducing energy consumption. The automated control system uses high-precision sensors to monitor key parameters such as kiln temperature, pressure, and material filling rate in real time, and precisely controls equipment operation based on iron oxide calcination process requirements, ensuring uniform product quality.

After completion, the project will help enterprises efficiently produce high-quality iron oxide products that meet the high-end market demand, meeting the stringent requirements of the coatings, ceramics, and other industries for high-quality raw materials, and promoting the upgrading and development of related industries. With advanced technology, enterprises can reduce production costs, enhance market competitiveness, and play a positive demonstration role in energy saving and emission reduction, injecting strong development momentum into regional economic development in the field of materials manufacturing.

Related Products

Coke oven

-

Chongqing Kelke New Materials Co., Ltd. 1.5 million tons/year new energy-saving ramming mass heat recovery coke oven

Chongqing Kelke New Materials Co., Ltd. actively responds to the industry's call for green and efficient development, and is fully promoting a project for a new energy-saving ramming heat recovery coke oven with an annual output of 1.5 million tons. This project is of great significance and injects new vitality into the development of the enterprise and the industry.

-

Vietnam and Fa Group 2*20 holes

Coke oven phase three project with heat recovery

-

Vietnam and Fa Rong Ju Steel Group Co., Ltd.

2#160T Dry Quenching Coke Bricklaying and Installation Project

-

The construction project of the 800,000-ton 4*18-hole phase-one coke oven at Eastern Steel, Malaysia

Malaysia's Eastern Steel is actively expanding its steel industry layout and is vigorously promoting the construction of its 800,000-ton 4*18-hole Phase I coke oven project. This project is of great significance and will inject strong impetus into the company's development.

-

The construction project of the 800,000-ton 4*18-hole Phase II coke oven at Eastern Steel, Malaysia

Malaysia's Eastern Steel continues to cultivate the steel industry, fully promoting the construction of an 800,000-ton 4*18-hole Phase II coke oven project, and continuing to write a new chapter in the company's development. This project is a key move for Eastern Steel to expand its production scale and enhance its industrial competitiveness.

-

Iran's TBAS 450,000-ton/6*17-hole clean heat recovery coke oven

Iran's TBAS focuses on the sustainable development of the energy industry and is vigorously promoting a 450,000-ton/6×17-hole clean heat recovery coke oven project. This project occupies a key position in Iran's industrial layout and is an important engine for upgrading the local coke industry.

-

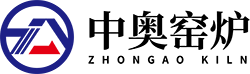

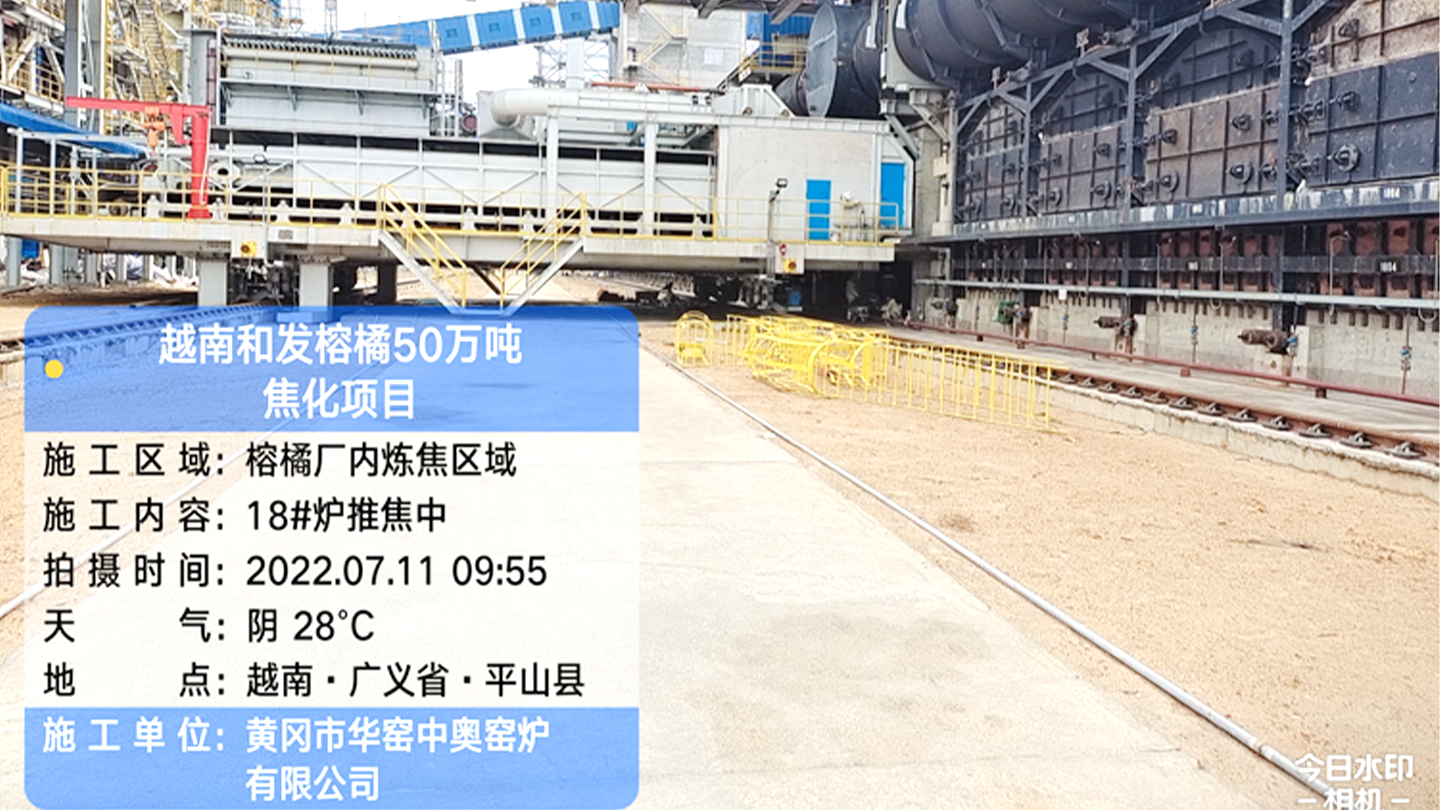

500,000-ton coking project for Vietnam and Faro

Vietnam and Pharong Citrus are actively involved in the expansion and upgrading of the energy industry, fully promoting the 500,000-ton coking project. This project occupies an important strategic position in Vietnam's industrial landscape and is a key force in promoting the development of the local coke industry.

-

Vietnam and Faro citrus 500,000-ton coking project

Vietnam and Pharoh Orange Group focus on energy industry upgrading, striving to build a 500,000-ton coking project, which is of great significance to Vietnam's industrial development.

-

Vietnam and Fa Group Phase III Project of 2*20-hole heat recovery coke oven

Vietnam and Fa Group actively expands its energy industry portfolio, fully promoting the Phase III project of the 2*20-hole heat recovery coke oven. This project is of great significance to the group's development and injects new impetus into the development of Vietnam's coking industry.

-

Sanming Sangang 12*14 hole coke oven hot recovery masonry project in Fujian Province

Sanming Sangang in Fujian Province, focusing on industrial upgrading and sustainable development, is vigorously promoting the construction of a 12*14 hole coke oven heat recovery project. This project occupies a key position in Sangang's strategic layout and has a profound impact on the progress of the local steel industry.

-

Tata Steel India's 1.6 million tons per year hot recovery coke oven

Tata Steel India, a leading industry player, is actively promoting a 1.6 million tons per year hot recovery coke oven project to further strengthen its competitiveness. This project is crucial to Tata Steel's strategic layout and has a profound impact on the development of India's steel industry.

-

Zhongmei Group Taigu Coke 1 million tons/year heat recovery coke oven

China Coal Group is actively involved in the construction of the Taigu Coking 1 million tons/year heat recovery coke oven project to enhance its influence in the coking industry and promote industrial upgrading. This project is of great significance in China Coal Group's strategic layout and plays a demonstrative and leading role in the development of the coking industry in Shanxi and even the whole country.

-

India's BHUSHAN Steel Company's 800,000-ton/year waste heat recovery coke oven

To solidify its position in the steel industry, India's BHUSHAN Steel Company is actively promoting industrial upgrading and is fully committed to building an 800,000-ton/year hot-recovery coke oven project. This project occupies a key position in the company's strategic layout and is of great significance to the development of India's steel industry.

-

Shanxi Qinze Coking Co., Ltd.'s 400,000-ton/year heat recovery coke oven

Shanxi Qinze Coking Co., Ltd., in order to adapt to the development trend of the coking industry and enhance its competitiveness, is vigorously promoting a 400,000-ton/year heat recovery coke oven project. This project occupies a core position in the company's development strategy and has a positive promoting effect on the upgrading of Shanxi's coking industry.

-

Xinggao Coking Plant's 800,000-ton-per-year, 8x10-hole heat recovery coke oven in Gaoping, Shanxi

The 8xl0-hole heat recovery coke oven project of Shanxi Gaoping Xinggao Coking Co., Ltd., constructed by our company, has won the honorary title of "Model Enterprise for Energy Conservation and Greenhouse Gas Emission Reduction in Chinese Towns and Villages" awarded by the United Nations Environment Programme, the United Nations Industrial Development Organization, and the Global Environment Fund Ministry of Agriculture of the People's Republic of China, due to its excellent construction quality, environmental protection, energy efficiency, and compliance with gas emission standards. It has also become a model project for learning and training by large coking plants both domestically and internationally.

-

Vietnam and Fa Group's 800,000 tons/year heat recovery coke oven

The 800,000-ton/year heat recovery coke oven of Vietnam and Fa Group demonstrates remarkable industrial strength. Designed by China ENFI Engineering Technology Co., Ltd., this advanced coke oven boasts an annual production capacity of 800,000 tons, efficiently meeting large-scale production demands.

-

Waste heat recovery of coke oven bottom and desulfurization and dust removal equipment

The 800,000-ton/year heat recovery coke oven and associated waste heat boiler and desulfurization and dust removal equipment of Vietnam and Fa Group are technologically advanced and functionally excellent. As a key part of the waste heat recovery system, the waste heat boiler efficiently gathers waste heat from coking. Its unique structural design makes heat absorption and transfer more efficient, achieving full utilization of energy. The high-temperature steam generated can be used for power generation or industrial production, reducing energy consumption costs.

-

Waste heat recovery coke oven flue gas circulation system

The waste gas circulation system, meticulously crafted by Vietnam and Fa Group for their 800,000-ton/year heat recovery coke oven, is core equipment for achieving efficient and clean production. Through ingenious process design, the system reintroduces some of the waste gas generated by coke oven combustion back into the combustion area for circulation. In this process, the waste gas plays a role in diluting the combustion air and balancing the temperature distribution inside the furnace, significantly improving combustion efficiency.

-

100,000-ton-per-year lanthanum carbon furnace

This coke oven, with an annual output of 100,000 tons, is a high-efficiency and high-quality equipment for producing coke. It adopts advanced external heating vertical pulverized coal pyrolysis technology, using low-rank lignite as raw material, and through precise pyrolysis reaction, it stably produces high-quality coke. At the technical level, the furnace body structure is ingeniously designed, which can effectively control the reaction process, ensure the pyrolysis process is efficient and stable, and greatly improve the coke production efficiency.

-

65-hole 4.3m coke oven

The 65-hole 4.3m coke oven is a key piece of equipment for efficient coking in the metallurgical and chemical industries. Its body consists of carbonization chambers, combustion chambers, and regenerator chambers. 65 carbonization chambers are arranged alternately with combustion chambers, each combustion chamber containing 20-30 vertical flues; the structure is scientific and reasonable.

-

Coke oven steel structure installation

The installation of the 65-hole 4.3m coke oven steel structure is a complex and crucial project. At the beginning of the installation, a professional team carefully checked and pre-assembled various steel structural components according to precise design drawings to ensure that all components fit correctly. During the installation process, advanced lifting equipment was used to accurately lift and place furnace columns, steel beams, and other components weighing several tons to their designated positions.

-

1.2 million tons/year 5.5M machine coal chemical production system

The 1.2 million-ton-per-year 5.5M coke oven chemical production system is a key facility for the efficient production of coke and various chemical products. Its annual production capacity reaches 1.2 million tons, demonstrating a significant scale advantage. This system uses advanced technology to conduct in-depth processing of the crude coal gas generated during the coking process. Through a series of processes such as condensation, absorption, and distillation, various high-value-added chemical products such as crude benzene, tar, and ammonium sulfate can be separated.

-

1 million tons/year 6.25M machine coke oven chemical production system

A 1 million-ton-per-year 6.25M coke oven chemical production system, a paragon of excellence in the coking industry. Its impressive annual capacity of 1 million tons provides a solid foundation for large-scale production. Relying on advanced technology, this system performs comprehensive and in-depth processing of the crude coal gas generated during coking. Through condensation, high-temperature tar and water vapor are separated from the gas; using absorption and distillation techniques, valuable chemical products such as crude benzene and ammonium sulfate are successfully refined.

-

Coke oven carbonization chamber

Coke oven chambers are the core of the coking process. Taking a typical coke oven as an example, its interior is a narrow rectangular structure, carefully built with high-quality silicon bricks, capable of withstanding temperatures exceeding 1000℃. During coking, coal is precisely fed into the carbonization chamber, where it is heated and decomposed in the absence of air. As the temperature gradually increases, the coal undergoes several stages: drying, pyrolysis, semi-coke formation, and coke maturation.

-

Annular heating furnace

A ring furnace is a highly efficient industrial heating device. Its unique ring structure design consists of a furnace body, a combustion system, and an exhaust system. The furnace body is circular, and the material being heated moves in a ring channel, resulting in more even heating. The combustion system is equipped with multiple burners, evenly distributed around the furnace wall. The flame size and temperature can be flexibly adjusted according to process requirements, ensuring complete fuel combustion and a thermal efficiency of over 80%.

-

Step-beam type heating furnace

The walking beam furnace is an important piece of equipment in industrial heating. It mainly consists of a furnace body, a walking beam mechanism, a combustion system, and a temperature control system. The furnace body is constructed of high-quality refractory materials to effectively reduce heat loss. The walking beam mechanism acts like a material 'transport track', pushing materials to move orderly within the furnace through periodic lifting, advancing, lowering, and retreating actions to achieve continuous heating. The combustion system is equipped with high-efficiency burners, accurately controlling fuel supply and combustion intensity based on process requirements to ensure stable heat output.

-

Automotive wheel hub heat treatment furnace

The automotive wheel hub heat treatment furnace is core equipment that ensures the quality and performance of automotive wheel hubs. Its furnace body adopts a multi-layer composite insulation structure, with an inner layer of high-temperature alloy material and an outer layer of high-quality heat insulation material, effectively reducing heat loss and improving energy utilization. The furnace is equipped with a high-precision temperature control system that can control temperature fluctuations within a very small range, ensuring the temperature accuracy during the wheel hub heat treatment process and meeting the stringent requirements of different material wheel hubs for heat treatment temperature.

-

Sponge iron tunnel kiln

Sponge iron tunnel kilns are key equipment in sponge iron production, providing high-quality raw materials for the steel industry. The kiln body is long and tunnel-shaped, typically consisting of a kiln head, kiln body, and kiln tail. The kiln body uses special refractory materials and insulation structures to effectively withstand high temperatures and reduce heat loss, ensuring thermal stability during the production process.

Coke oven hot repair project

-

Hebei Taihang Iron and Steel Coke Oven Hot Repair

As a key player in the industry, Hebei Taihang Steel's stable operation of its coking chambers is crucial to production. To ensure production efficiency and product quality, and to extend the service life of the equipment, a full-scale coking chamber hot repair project is underway.

-

Jilin Xinda Coking Plant's Clean Coke Oven Large Wall Repair

As the core production equipment, the stability of the large wall of the clean coke oven at Jilin Xinda Coking has a significant impact on production efficiency, environmental performance, and product quality. To ensure the efficient and stable operation of the coke oven, Xinda Coking is fully committed to the maintenance project of the clean coke oven's large wall.

-

Repair of underground flue in a clean coke oven at Mingyuan Coking Plant in Qinshui, Shanxi

The underground flue of the clean coke oven at Shanxi Qinshui Mingyuan Coking Co., Ltd. is a key passage for ensuring the normal operation of the coke oven, and its condition directly affects production efficiency, energy consumption, and environmental protection effects. Given that the underground flue has been subjected to high temperatures, corrosive gases, and complex geological environments for a long time, resulting in varying degrees of damage, Mingyuan Coking has actively carried out underground flue repair projects.

New energy kiln

-

Guizhou Jiashang New Energy Materials Co., Ltd.'s 100-meter lithium manganate material electric heating three-channel tunnel kiln

Guizhou Jiashang New Energy Materials Co., Ltd. focuses on the booming development of new energy materials and is fully promoting the 100-meter lithium manganese oxide material electric heating three-channel tunnel kiln project. This project is an important measure for the company to improve production efficiency, optimize product quality, and enhance market competitiveness.

-

Lithium battery anode material roller kiln

Against the backdrop of surging global demand for lithium batteries, improving the production process and quality of anode materials has become critical for the industry. A certain company is actively responding to market demands, fully promoting a lithium battery anode material roller kiln project, aiming to enhance its competitiveness in the lithium battery materials field.

-

Lithium-ion battery anode material roller kiln

With the vigorous development of the new energy vehicle and energy storage industries, the demand for lithium batteries has exploded, placing stringent demands on the quality and output of anode materials. Against this backdrop, the lithium battery anode material roller kiln project has emerged as a key driver of industry development.

-

Tunnel kiln for lithium battery anode materials

Amidst the global push for green energy transformation, the new energy vehicle and energy storage sectors are experiencing rapid growth. Lithium batteries, as core energy storage components, are seeing a surge in market demand, placing extremely high requirements on the quality and output of negative electrode materials. In this context, the lithium battery negative electrode material tunnel kiln project has been launched, becoming an important engine driving industry progress.

-

Lithium-ion battery anode material roller kiln under construction

Against the backdrop of the global push for green energy transformation, the new energy vehicle and energy storage industries are booming, with continuous high demand for lithium batteries, and increasingly stringent requirements for the quality and output of negative electrode materials. Capitalizing on this opportunity, the lithium battery anode material roller kiln project is fully underway, striving to inject strong impetus into industry development.

Glass furnace

-

52 square horseshoe flame glass melting furnace

Against the backdrop of growing demand for glass products in industries such as construction, automotive, and electronics, improving glass melting efficiency and quality has become crucial for industry development. To meet the market demand for high-quality glass, the 52-square-meter horseshoe flame glass melting furnace project was born.

-

Pre-installation of electrofused zirconia corundum bricks in a 66-square-meter horseshoe flame glass melting furnace

With the continued growth in demand for high-quality glass in industries such as construction, automotive, and electronics, optimization of glass melting technology is crucial. The 66-square-meter horseshoe flame glass melting furnace, as key equipment, its melting pool masonry quality directly affects the production quality and efficiency of glass. Against this backdrop, the pre-construction project for the melting pool electro-fused zirconia corundum brick is launched.

-

48-square-meter horseshoe flame glass melting furnace

With the increasing demand for high-quality glass across various industries – from the architectural and decorative sectors prioritizing aesthetics and variety, to the automotive industry focusing on safety and comfort, and electronics striving for thinness and high-definition displays – the need for innovative glass melting technology is paramount. The 48-square-meter horseshoe flame glass melting furnace project emerges as a timely response to this growing market demand for superior glass, aiming to propel the glass manufacturing industry to new heights.

-

Microcrystalline glass melting furnace

With the pursuit of ultimate texture in architectural decoration, the increasing demand for precision display components in high-end electronic devices, and the stringent requirements for high-performance materials in aerospace and other fields, microcrystalline glass, as a new type of material with both glass and ceramic properties, has seen a continuous rise in market demand. Against this backdrop, the microcrystalline glass melting furnace project has been launched to fill the market gap and promote the development of the microcrystalline glass industry.

-

Microcrystalline glass sintering tunnel kiln

With the booming development of the construction decoration, electronic information, and energy industries, the demand for high-performance glass-ceramics has exploded. Glass-ceramics, with their excellent mechanical properties, chemical stability, and optical characteristics, have become key materials in many high-end Applications. Under this situation, the glass-ceramics firing tunnel kiln project has emerged, aiming to meet the urgent market demand for high-quality glass-ceramics and to propel the glass-ceramics industry to new heights.

-

400t/d glass melting furnace

With the surge in demand for curtain wall glass in the construction industry, the automotive industry's pursuit of panoramic sunroofs and high-definition displays, and the packaging industry's preference for exquisite glass containers, the glass market is showing strong growth. To meet the growing market demand and improve glass production efficiency and quality, the 400t/d glass melting furnace project has been launched.

Graphite/Carbon

-

Qixian Danyuan Graphite Electrode Furnace Masonry and Installation Project, Jincheng County, Shanxi Province

Against the backdrop of the booming steel, metallurgical, and chemical industries, the demand for high-quality graphitized electrodes continues to climb. To meet market demand and improve its production capacity and product quality, Qixian Danyuan in Jincheng County, Shanxi Province, is actively promoting the construction and installation of graphitized electrode furnaces.

-

Gede New Materials Co., Ltd. Ceramic Graphite Furnace

With the rapid development of new materials, high-performance ceramic materials, with their excellent properties, are in increasing demand in many cutting-edge industries such as electronics, aerospace, and new energy. In order to meet market trends and enhance its competitiveness in new materials R&D and production, Gede New Materials Co., Ltd. is fully promoting the ceramic graphitization furnace project.

-

graphitization furnace

With the rapid advancement of technology, the new energy vehicle, energy storage equipment, and high-end electronics industries are booming, leading to an explosive growth in the demand for high-quality graphite materials. To meet the increasingly stringent market requirements for graphite materials and improve production efficiency, the graphitization furnace project has emerged.

-

Shanxi Biyuan Yufeng Materials Co., Ltd.'s 9 graphitization furnaces

Against the backdrop of the booming new energy vehicle industry, the surge in demand for energy storage equipment, and the continuous upgrading of electronic devices, the market demand for high-quality graphite materials has exploded. Shanxi Biyuan Yufeng Materials Co., Ltd. has seized this opportunity and is making every effort to promote the 9 graphite furnace project, aiming to meet market demand and enhance the company's core competitiveness.

-

Room 38, Calcining Furnace, Wando (Qinyang) Carbon Co., Ltd., Jiaozuo, Henan

With the continued expansion of industries such as steel and aluminum, the demand for high-quality carbon products is steadily increasing. Henan Jiaozuo Wandu (Qinyang) Carbon Co., Ltd. is actively planning and fully promoting the 38-chamber baking furnace project to enhance its production capacity and product quality.

-

Room 54, BaoTou SenDu Carbon Co., Ltd. Roasting Furnace

With the rapid development of industries such as steel, photovoltaics, and new energy, the demand for high-quality carbon products continues to grow. Baotou Sendu Carbon Co., Ltd. is actively promoting the construction of the No. 54 baking furnace project to adapt to market trends and enhance its competitiveness.

-

Graphite electrode production line equipment

With the rapid development of the steel, metallurgical, and chemical industries, the demand for high-quality graphitized electrodes has surged. To meet market demand and enhance the competitiveness of enterprises in the electrode production sector, the graphitized electrode production line equipment project has been launched.

-

Carbon baking furnace under construction

With the rapid development of new energy, steel, and chemical industries, the demand for high-quality carbon materials continues to rise. Carbon baking furnaces, as core equipment for producing high-quality carbon products, are of significant importance. The currently under-construction carbon baking furnace project responds to this market demand and aims to improve the quality and efficiency of carbon production.

-

Carbon baking furnace

With the rapid development of many cutting-edge industries such as new energy, steel, chemical industry, and electronics, the demand for high-quality carbon materials has shown explosive growth. As a key core equipment for producing high-quality carbon products, the carbon baking furnace occupies a pivotal position in the entire industry chain.

-

Shanshan Longsheng Carbon No. 36 Baking Furnace

In today's rapidly developing new energy, steel, and chemical industries, the market demand for high-quality carbon materials is increasing day by day. Shanshan Longsheng Carbon actively responds to the market's call, fully committed to building a 36-chamber baking furnace project, striving to improve the production level of carbon products and meet the urgent market demand for high-quality carbon products.

-

40,000-ton/year pre-baked anode open carbon furnace

In the rapid development of modern industry, the demand for high-quality prebaked anodes in industries such as aluminum smelting and steelmaking continues to grow. To meet the urgent market demand for high-quality and large-scale prebaked anodes, a 40,000-ton/year prebaked anode plate open carbon furnace project has been launched.

-

Coke calcination furnace in room 68

With the rapid development of new energy, steel, chemical and other industries, the demand for high-quality carbon materials has shown explosive growth. To meet the urgent market demand for large-scale, high-quality carbon products, the No. 68 carbon baking furnace project came into being.

-

24-can carbon-based forging furnace

With the rapid development of new energy, metallurgy, and chemical industries, the demand for high-quality carbon materials has increased dramatically. To meet the market's urgent need for efficient and stable production of high-quality carbon products, the 24-tank carbon baking furnace project has been launched.

Metallurgical furnace

-

Construction of the expansion project for the flash furnace of Serbia Zijin Copper

Against the backdrop of rising global demand for copper resources, Zijin Serbia Copper Industry is actively promoting the construction project of the flash smelting furnace expansion project to further improve its copper smelting capacity and enhance its competitiveness in the international copper market.

-

Shanxi Xiaoyi Dongyi Group's annual production of 30,000 tons of single-sided double-row double-heat recuperative reduction furnace

With the rapid development of the steel and non-ferrous metals industries, the demand for high-quality reducing agents and efficient smelting processes is increasing day by day. Shanxi Xiaoyi Dongyi Group, in order to adapt to market trends and enhance its competitiveness in the smelting field, is making every effort to promote the annual production of 30,000 tons of single-sided double-row double-heat recovery reduction furnace project.

-

Xinjiang Tengxiang Magnesium Products Co., Ltd.'s annual production of 15,000 tons of double-sided single-row single heat storage reduction furnace

With the rapid development of aerospace, automotive manufacturing, and electronic communications industries, the demand for lightweight and high-strength magnesium products has exploded. Xinjiang Tengxiang Magnesium Products Co., Ltd. has keenly captured market opportunities and is vigorously promoting a project for an annual output of 15,000 tons of double-sided single-row single-heat-storage reduction furnaces, aiming to improve magnesium product production capacity and quality, and enhance the company's market competitiveness in the magnesium industry.

-

Hot blast stove for blast furnace

Under the prevailing trend in the steel industry of pursuing highly efficient, energy-saving, and high-quality production, blast furnace ironmaking, as a core process, has increasingly stringent requirements for the stability and quality of hot air supply. To improve blast furnace ironmaking efficiency and reduce energy consumption, blast furnace hot stove projects have emerged.

-

1760 cubic meter blast furnace

Driven by the booming development in fields such as construction, machinery manufacturing, and the automotive industry, the market demand for steel, as a basic raw material, continues to climb. To meet this demand and improve steel production efficiency and quality, the 1760 cubic-meter blast furnace project has been officially launched.

-

Oxygen-protected reduction roller kiln

In the field of new material research and development and production, many materials have extremely strict requirements for the firing environment, which traditional kilns cannot meet. Against this backdrop, the oxygen-protected reduction roller kiln project has emerged to provide more precise and high-quality firing conditions for material processing.

-

Tungsten powder, ferroalloy powder reduction furnace

In modern industrial systems, tungsten powder and ferroalloy powder, as key basic materials, are widely used in many high-end fields such as aerospace, mechanical manufacturing, and electronic information. With the continuous growth of demand for high-performance powder materials in related industries, higher requirements have been put forward for the performance and process of reduction furnace equipment. Under this situation, the tungsten powder and ferroalloy powder reduction furnace project has been officially launched, aiming to provide advanced and efficient reduction equipment for powder material production.

-

Secondary reduction belt furnace

In industries such as powder metallurgy and new energy materials, the extreme pursuit of material purity and performance has driven continuous innovation in production processes. Materials after a single reduction often fail to fully meet the needs of high-end applications, thus leading to the development of the secondary reduction belt furnace project. This project aims to further optimize material quality and enhance industrial competitiveness.

-

20,000-ton-per-year metal magnesium calcining reduction furnace

Against the backdrop of the lightweight trend in new energy vehicles, the demand for high-performance materials in 3C products, and the booming aerospace industry, magnesium metal, due to its excellent lightweight properties and good mechanical properties, has seen explosive market growth. To meet this market demand and improve the scale and quality of magnesium metal production, the 20,000-ton-per-year magnesium metal calcination and reduction furnace project has officially been launched.

Ceramic kiln

Brick and tile building materials

-

Shanxi Shuozhou Jin-Yu Integrated New Materials Co., Ltd.'s annual production of 15,000 tons of Class A high-alumina bricks fully automatic tunnel kiln

With the continuous development of high-temperature industries such as steel, cement, and glass, the demand for high-quality refractory materials is growing. First-class high-alumina bricks, as a key refractory material, are widely used in various high-temperature kilns due to their high refractoriness, good erosion resistance, and mechanical strength. Against this backdrop, Shanxi Shuozhou Jinyu Integrated New Materials Co., Ltd. has launched a 15,000-ton annual output fully automatic tunnel kiln project for first-class high-alumina bricks, aiming to meet market demand and enhance the company's competitiveness in the refractory materials field.

-

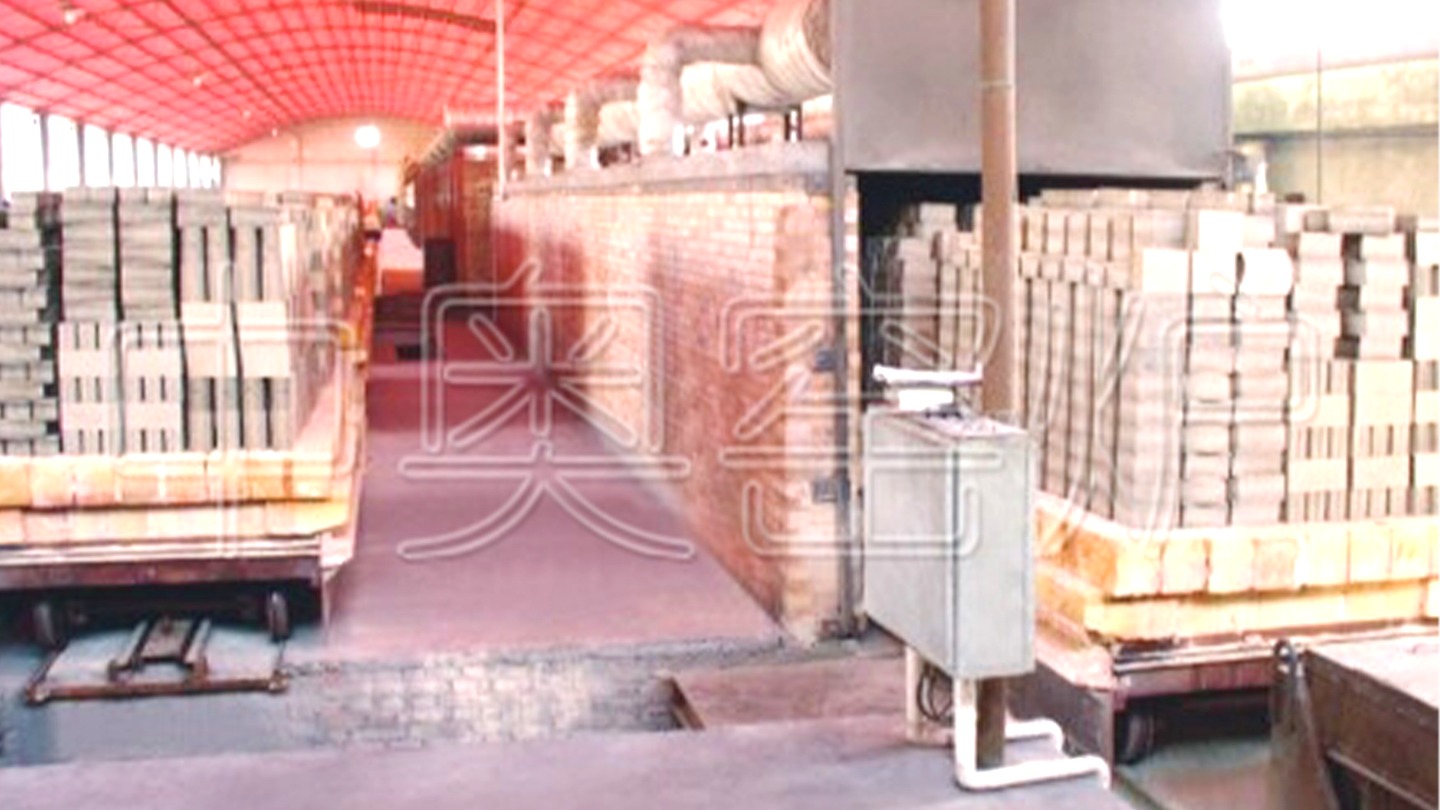

82-meter high-temperature tunnel kiln

With the booming development of industries such as ceramics, refractory materials, and magnetic materials, the demand for high-temperature firing equipment is increasing, and the requirements for the accuracy and stability of the firing process are becoming increasingly stringent. Under this situation, the 82-meter high-temperature tunnel kiln project was launched to provide efficient and high-quality firing solutions for related industries.

-

High-temperature firing tunnel kiln for refractory materials

With the continuous innovation and development of high-temperature industries such as steel, cement, glass, and non-ferrous metal smelting, increasingly stringent requirements have been placed on the performance and quality of refractory materials. To meet this trend and satisfy the needs of refractory material manufacturers for efficient and precise firing equipment, the refractory material high-temperature firing tunnel kiln project has emerged.

-

Refractory tunnel kiln

With the booming development of the steel, glass, cement, and ceramics industries, the demand for high-quality refractory materials in high-temperature production processes continues to rise. To meet this demand and improve the production efficiency and quality of refractory materials, the refractory materials tunnel kiln project is being actively promoted.

-

alkaline refractory materials ultra-high temperature tunnel kiln

With the advancement of industries such as steel and non-ferrous metal smelting towards high-end applications, the performance requirements for alkaline refractory materials are becoming increasingly stringent, and ultra-high-temperature firing has become a key step in improving their quality. Against this backdrop, the ultra-high-temperature firing tunnel kiln project for alkaline refractory materials has emerged to meet the urgent industry demand for high-quality alkaline refractory materials.

-

10.3-meter-wide coal gangue brick tunnel kiln

Driven by the green development trend in the construction industry, the demand for environmentally friendly wall materials is steadily increasing. Coal gangue bricks, with their energy-saving and waste-reducing properties, have gained significant popularity. To improve the production efficiency and quality of coal gangue bricks, a 10.3-meter wide coal gangue brick tunnel kiln project has been launched.

-

9.0-meter-wide tunnel kiln

In the wave of pursuing efficient and high-quality production in the ceramic, refractory materials, and building materials industries, higher demands are placed on the performance and capacity of kiln equipment. The 9.0-meter wide tunnel kiln project was launched to meet this trend, aiming to provide advanced firing solutions for related industries.

-

6.9-meter-wide tunnel kiln

With the continuous development of the ceramic, refractory materials, and building materials industries, the demand for refined and efficient kiln equipment is becoming increasingly prominent. Against this backdrop, the 6.9-meter-wide tunnel kiln project has emerged to provide a more suitable firing solution for these industries.

-

4.6-meter-wide tunnel kiln

In today's ceramics, brick and tile, and special materials industries, where the pursuit of refinement and energy efficiency is ongoing, increasingly stringent demands are placed on kiln equipment. The 4.6-meter inner-width tunnel kiln project is a direct response to this trend, dedicated to providing highly efficient and high-quality firing solutions for related industries.

Rare earth kiln

Cement/lime kiln

-

Anhui Liuan Iron and Steel Group's five 600T annual output double-shaft lime kilns

In the steel industry's ongoing pursuit of high quality, low cost, and green development, high-quality lime, as a key metallurgical auxiliary material, is crucial for stable supply and high-quality assurance. Anhui Liuan Iron and Steel Group, in order to strengthen its competitiveness in the industry and improve production efficiency and product quality, is fully promoting the construction of a project with five 600T double-Mertz lime kilns with an annual output.

-

Malaysia's United Steel four 600T annual output twin-hearth lime kilns

Against the backdrop of increasingly fierce competition in the global steel industry and the growing pursuit of green and efficient production, high-quality lime, as an indispensable key auxiliary material in steel smelting, plays a decisive role in the production efficiency and product quality of steel enterprises through its stable and high-quality supply. In order to enhance its competitiveness in the international steel market, Malaysia's United Steel is fully promoting the construction of a project with four 600T twin-shaft lime kilns with an annual output.

-

Guangxi Liuzhou Shanhai Technology's four 600T annual output hanging cylinder lime kilns

With the booming development of the construction, metallurgy, and chemical industries, the demand for high-quality lime continues to grow, and the requirements for efficient and environmentally friendly production processes are becoming increasingly stringent. Guangxi Liuzhou Shanhai Technology is fully promoting the construction of a project with four 600T annual output hanging-cylinder lime kilns to meet market trends and enhance its competitiveness in the lime production field.

-

Cement rotary kiln

Against the backdrop of comprehensively advanced infrastructure construction and accelerating urbanization, cement, as a core material in the construction industry, shows a sustained growth trend in market demand. To meet this demand and improve the quality and efficiency of cement production, the cement rotary kiln project has emerged.

-

Iron oxide rotary kiln

Driven by the booming development of numerous industries such as coatings, ceramics, electronics, and magnetic materials, the demand for high-quality iron oxide has seen explosive growth. To meet this market demand and improve the quality and efficiency of iron oxide production, the iron oxide calcination rotary kiln project has emerged.

-

Twin/single-shaft lime vertical kiln

With the continuous development of the steel, chemical, and construction industries, the demand for lime is increasing day by day, and the requirements for lime quality are becoming increasingly stringent. In order to meet market demand and improve lime production efficiency and quality, double-body/single-body lime vertical kiln projects are being actively promoted.

-

Cement vertical kiln

Against the backdrop of accelerating infrastructure construction and steady urbanization, cement, as a key material in the construction industry, continues to see strong market demand. To align with this trend and improve cement production efficiency and quality, the cement vertical kiln project has commenced construction.

-

Rotary kiln for alumina calcination

Against the backdrop of the booming global aluminum industry and the surging demand for high-performance aluminum materials from sectors such as new energy vehicles and aerospace, high-quality alumina, as the core raw material for aluminum smelting, is experiencing a continuous increase in market demand. To meet this demand and improve the quality and efficiency of alumina production, the alumina rotary kiln project has been launched.

-

Rare earth calcination rotary kiln

In today's rapidly developing global technology, rare earth, as an "industrial vitamin," is widely used in many strategic emerging industries such as electronic information, new energy, and aerospace. The market demand for high-purity, high-quality rare earth products is increasing day by day. To meet this demand and improve the quality and efficiency of rare earth processing, the rare earth calcination rotary kiln project has been launched.

-

High-purity rare earth oxide roller kiln

With the rapid development of cutting-edge fields such as electronics, optics, and new energy, the demand for high-purity rare earth oxides has exploded. These materials play a key role in high-end electronic products, laser equipment, and high-performance batteries, and the market's requirements for their purity and quality are almost demanding. To meet this high-end demand and improve the production quality and efficiency of high-purity rare earth oxides, the high-purity rare earth oxide roller kiln project has been launched.

-

High-alumina clay rotary kiln

Kaolin, as an important non-metallic mineral raw material, is widely used in numerous industries such as ceramics, papermaking, coatings, and rubber. With the ever-increasing demand for higher quality kaolin in various industries, efficient and high-quality calcination processes have become crucial. The kaolin calcination rotary kiln project is launched in response to this market demand, aiming to improve the processing quality and production efficiency of kaolin.

Get a Product Quote

Contact Us

Tel: 86-0713-8663193

Yu Yuanlin: 86-13871998019

Hong Hui: 86-13907259535

Yu Shiyun: 86-17798384875

E-mail:zhongaokiln@163.com

Address: Building A3, Guanggu United Science and Technology City, Huangzhou District, Huanggang City, Hubei Province